Resiliency

Resiliency

How high-performance gypsum boards cut risk in commercial projects

Design resilience into buildings with specialty gypsum boards

Bringing a building from an idea into reality involves hundreds of decisions. Each one balances occupant needs, building code requirements, costs and construction scheduling. The building’s resiliency — or long-term performance — can be overlooked in this equation.

Consider the point of view of the different stakeholders to understand the tensions between these competing priorities.

- Architects combine technical know-how and creativity to design structures that are functional, safe and aesthetically pleasing within budget constraints. They ask, “What will make this building work best for occupants?”

- Contractors bring real-world construction experience and their bottom line to evaluate every product selection and scheduling decision. They ask, “Where should I spend to ensure the best profit and craftsmanship?”

- Building owners consider not only the overall project price but also the facility’s functionality and maintenance needs throughout its existence. They ask, “Will my investment pay off?”

This article examines when architects, contractors and building owners should invest in high‑performance specialty gypsum boards—manufactured by Gold Bond Building Products, LLC, an affiliate of National Gypsum Company—to deliver wall‑to‑wall resilience. It examines how products in the Gold Bond® XP® family and the Gold Bond® eXP® family of high-performance gypsum boards can help:

- Reduce wear and tear

- Guard against moisture damage

- Protect against construction schedule delays

- Improve acoustics

What are the risks of value engineering?

Contractors and building owners sometimes use value engineering to save on costs or make up for budget shortages.

Value engineering aims to balance budget and functionality by prioritizing building materials that lower the overall cost of the project with minimal performance loss. When it comes to choosing gypsum boards, this practice often downgrades the specified high-performance gypsum board to standard gypsum boards, which can increase risks from:

- Damage from the elements during construction, causing schedule delays

- Diminished long-term resilience from moisture, mold and mildew damage

- Increased wear and tear from daily use, resulting in higher maintenance costs

- Dissatisfied tenants or low productivity due to substandard acoustic performance, resulting in costly and disruptive renovations

Abuse- and impact-resistant gypsum boards reduce wear and tear over the long term

After a new facility goes into service — whether it’s a hospital, high school or office — the property owner implements a maintenance schedule to keep it functioning safely and smoothly. Upgrading from standard drywall to high-performance products, such as Gold Bond® XP® Hi-Abuse® Gypsum Board and Gold Bond® XP® Hi-Impact® Gypsum Board, reduces wear and tear.

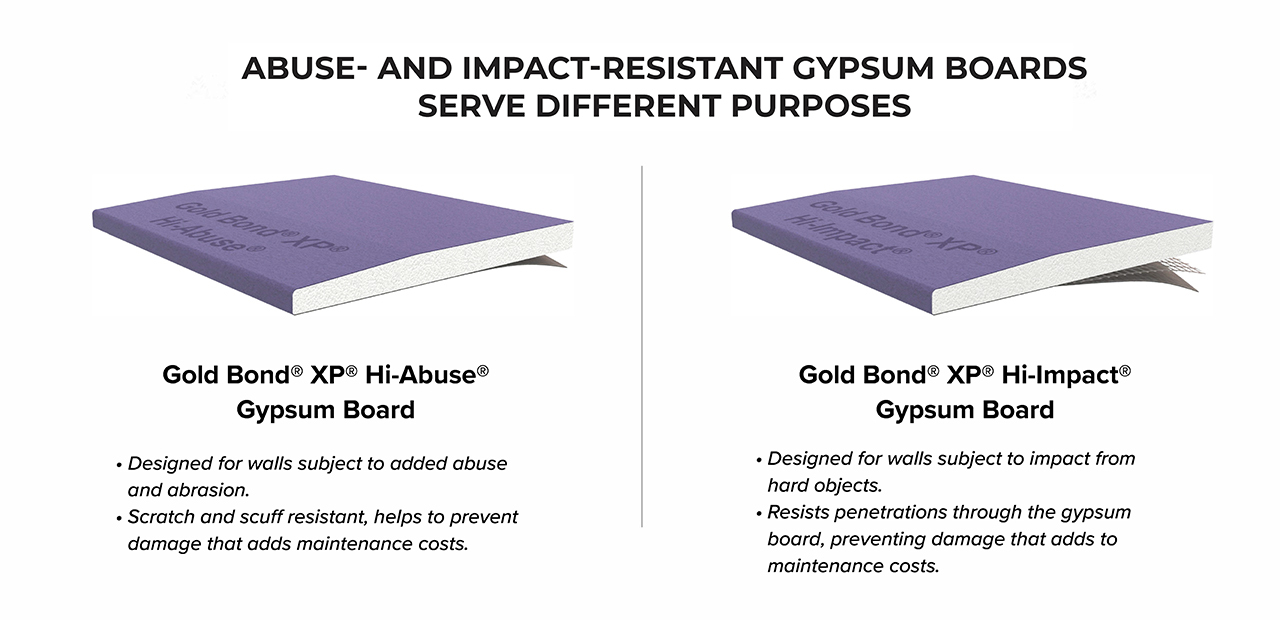

Different purposes for abuse- and impact-resistant gypsum board

Different purposes for abuse- and impact-resistant gypsum board"There is definitely confusion over abuse and impact. The impact-resistant gypsum board has fiberglass mesh in its core to prevent penetrations, but if the spec isn’t clear, all the contractor sees is a higher price. They will choose abuse-resistant products based on price, but they do not perform the same as impact-resistant products."

Jessica Janosko

Jessica Janosko

Southeast Area Sales ManagerNational GypsumReal-world scenario: An architect designing a hospital decides to use impact-resistant gypsum board in a corridor to reduce damage from gurneys. However, the specification document combines abuse and impact as seen in the example on the left below. The drywall contractor, seeking to control costs, selects the less costly option: abuse-resistant gypsum board. During a site visit, the architect finds the error and requests the correct product be installed, resulting in additional costs and schedule delays.

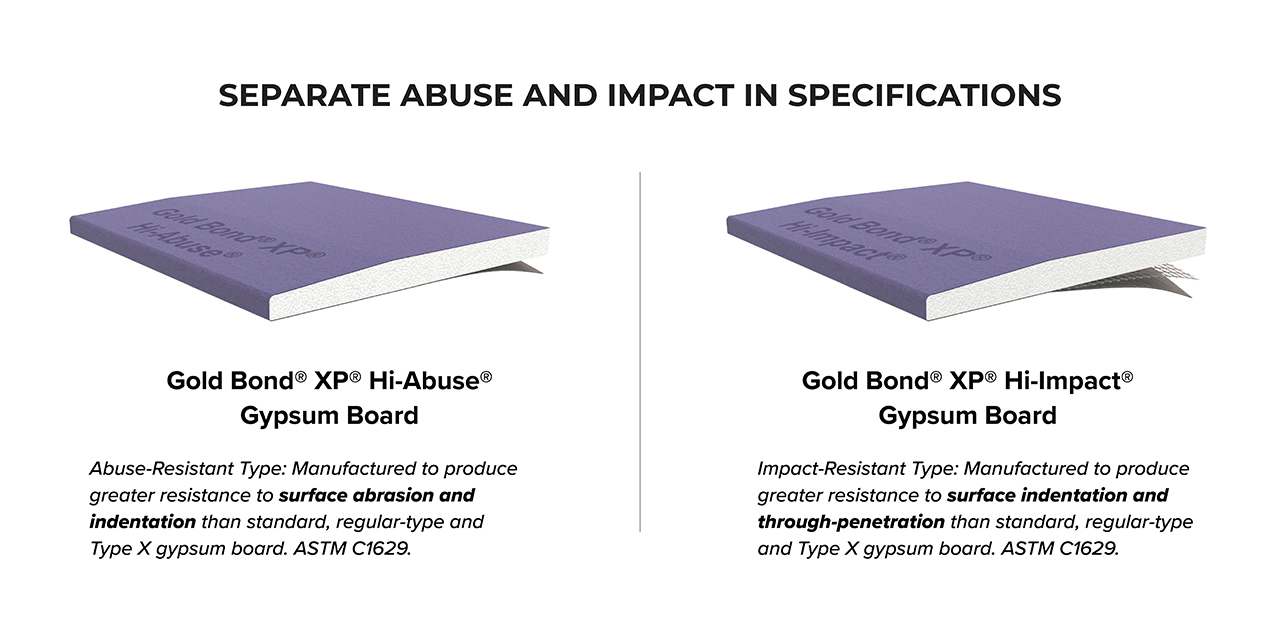

Difference in specifications for abuse- and impact-resistant gypsum board

Difference in specifications for abuse- and impact-resistant gypsum boardWhere should abuse-resistant and impact-resistant gypsum boards be specified?

Use XP Hi-Abuse Gypsum Board to prevent surface abrasions such as scuffs and scratches in high-traffic areas.

- Challenge: School hallways are crowded with students carrying backpacks, sports equipment and band instruments, resulting in wall scuffs, scrapes and abrasions if standard drywall is used.

- Solution: XP Hi-Abuse Gypsum Board has a denser, mold- and moisture-resistant Type X gypsum core encased in abrasion-resistant PURPLE® face paper on the face side to reduce surface-level damage. Typical maintenance of XP Hi-Abuse products includes painting. Standard gypsum boards can be damaged enough to require patching gouges with joint treatment and repainting.

Resource alert

Dec. 12, 2025

Read this article to understand the difference between impact-resistant and abuse resistant gypsum boards.

Read article

Use XP Hi-Impact Gypsum Board in corridors with wheeled traffic.

- Challenge: Hospital corridors are a gauntlet of gurneys, computer carts and diagnostic machines being pushed by healthcare workers on a mission. Each has the potential to penetrate the wall cavity or gouge drywall. Large repairs aren’t limited to materials and labor; they also disrupt the facility’s operations and cause unwanted noise and mess. In addition, hospital corridors use fire-rated walls, so the repair requires more time and expertise to maintain the fire rating.

- Solution: XP Hi-Impact Gypsum Board has a denser, mold- and moisture-resistant Type X gypsum core encased in abrasion-resistant PURPLE face paper on the face side and fiberglass mesh embedded in the core to prevent impacts and penetrations. A gurney can penetrate through standard drywall into the wall cavity, which requires extensive patching and finishing to repair. Similar collisions with XP Hi-Impact typically limit intrusion into the stud cavity, making it easy to repair with joint compound and paint.

Download the Where to specify Hi-Abuse and Hi-Impact gypsum boards infographic.

Glass mat shaftliner panels guard against weather exposure damage in shaft enclosures and area separation walls

High humidity or rain damage to paper-faced gypsum panels installed in shaft enclosures and area separation walls before the building is weathertight is one of the most common challenges of large commercial and multifamily projects. Gold Bond® eXP® Shaftliner has a Type X gypsum core encased in a coated, specially designed PURPLE fiberglass mat to resist damage from extended weather exposure.

Because shaft enclosures and area separation walls are constructed during the early phases of the building process, they are often left exposed to the elements for many months. High humidity or repeated rain events can cause:

- Paper facing delamination

- Increased mold and mildew susceptibility

- Board deterioration

Real-world scenario: A contractor building a luxury condo building in Florida uses paper-faced shaftliner panels in the elevator shaft enclosures because the 30-day forecast shows only a few low chances of rain. Material delivery delays and an unexpected hurricane result in heavy rain before the building has been dried in, leaving the contractor with water cascading down the shaft enclosures. The water-damaged panels may have to be replaced.

“Water always finds the lowest point, so it’s always the bottom part of the elevator shaft, where water can pool, that has to be replaced,” Janosko said. “But you can’t replace the bottom of the shaft without replacing the top part as well. That’s a lot of time and expense to repair.”

While shaft enclosures and area separation walls can be constructed with paper-faced gypsum panels, such as Gold Bond® Shaftliner XP®, contractors must carefully weigh the risks of doing so. Shaftliner XP panels have mold-, mildew- and moisture-resistant core and cover paper that provide extra protection against moisture damage, but they do not protect against weather exposure, such as repeated rain showers.

Gold Bond eXP Shaftliner protects shaft enclosures and area separation walls from weather exposure damage during construction, as well as moisture, mold and mildew throughout the life of the building. These panels include:

- Superior mold and moisture resistance: Core is encased in a coated, specially designed PURPLE fiberglass mat on the face, back and sides to reinforce and protect the core.

- 12-month exposure warranty: Effective for 12 months from the date of installation to provide peace of mind come rain or shine.

- Type X core: Fire resistant and approved for use in 1- to 4-hour UL shaftwall assemblies and 2-hour UL fire-rated area separation wall designs.

Acoustic gypsum boards help building owners avoid costly and disruptive renovations

The disruptive nature of noise is well established. There are numerous acoustic challenges in the places where we live, work and learn:

- People expect conversations in their doctor’s office to remain private.

- No one wants their co-workers to overhear sensitive work evaluation discussions.

- Teachers want their students to be able to focus and not be distracted by noise in neighboring classrooms.

- Everyone wants to get a good night’s sleep when they stay in a hotel.

Adding Gold Bond® SoundBreak® XP®, which is part of the XP Family of Products, in the design and ensuring that it is installed can save architects and contractors callbacks down the road.

Real-world scenario: An architect designing a five-story commercial building doesn’t notice the building’s generator is located next to a conference room and specifies standard drywall. When the building opens and people start working in the office,

they instantly complain about the generator’s noise drowning out meetings. The situation results in a renovation that creates mess and disruption in the office.

“Everybody’s calling and saying, ‘We can hear this generator.’ And again, this generator’s powering a five-story building,” Janosko said. “On the generator side, they added an extra layer of 5/8" gypsum board and insulation and SoundBreak XP Gypsum Board on the wall inside the conference room to mitigate the sound of the generator.”

Despite the prevalence of complaints about substandard acoustic performance, acoustically enhanced gypsum boards, such as SoundBreak XP, are often removed from projects as a result of value engineering. Poor acoustic performance can trigger renovations to correct the problem.

Acoustic remediation renovations are not only costly but also disruptive:

- The area to be renovated must be closed or cordoned off.

- The renovation crew’s conversation and use of power tools create noise and disruptions.

- Finishing and painting the renovated wall adds dust and fumes to the interior space.

Based on acoustic testing, replacing standard gypsum board on one side of a wall assembly with SoundBreak XP can increase the assembly’s STC rating by up to 11 points.

Here’s how it works:

- SoundBreak XP consists of a viscoelastic polymer between two layers of high-density gypsum board to add damping to the assembly to reduce sound transmission.

- The viscoelastic polymer dissipates sound waves as they travel through the wall.

- The high-density gypsum board provides mass, which is one of the six variables that affect STC ratings.

Resource alert: Download The SoundBook® to see over 300 tested acoustic assemblies available to help you design quiet spaces.

Pre-rock construction with glass mat gypsum boards protects against costly schedule delays

Coordinating crews is one of the biggest challenges of large commercial builds. A single delay in one trade’s work can snowball through the entire schedule. Pre-rock construction can save time. This includes installing gypsum panels on the upper portions of walls (plenum areas) and the entirety of shaft enclosures before the building’s roof has been installed. With panels already in place, plumbing, electrical and HVAC trades simply cut holes for pipes, electrical lines and ductwork.

In large commercial builds, drywall installation often begins before the building is dried in, leaving everything inside exposed to the elements. Using paper-faced drywall before the building is dried in is prohibited by International Building Code, Section 2508.2.1 Weather Protection. It can also increase the risk of moisture damage and mold.

Gold Bond® eXP® Interior Extreme® Gypsum Panels are an ideal solution for pre-rock. The core of these panels is encased in coated fiberglass facers to protect it from moisture and mold. In addition to pre-rock applications, eXP Interior Extreme protects the interior face of exterior walls to reduce the risk of moisture damage before the building is enclosed. All eXP fiberglass-faced products come with a 12-month extended exposure warranty.

There are five eXP options for pre-rock applications:

- Gold Bond® eXP® Interior Extreme® Gypsum Panel is designed for use on all interior walls and ceilings and is recommended for pre-rock applications.

- Gold Bond® eXP® Interior Extreme® Fire-Shield® Gypsum Panel has a fire-resistant Type X core and is an approved component in UL-rated assemblies.

- Gold Bond® eXP® Interior Extreme® Fire-Shield C™ Gypsum Panel is available in 1/2" and 5/8" thicknesses, both of which have a fire-resistant Type C core approved as a component in UL-rated assemblies.

- Gold Bond® eXP® Interior Extreme® AR Gypsum Panel provides surface abrasion resistance for high-traffic corridors where surface scratches are a concern and has a Type X core approved as a component in UL-rated assemblies.

- Gold Bond® eXP® Interior Extreme® IR Gypsum Panel provides impact resistance for walls prone to penetrations and includes a Type X core approved as a component in UL-rated assemblies.

Cut risk, not corners, with specialty gypsum board products provided by National Gypsum Company

High-performance gypsum boards protect your investment from the first stages of construction through the service life of the building. Learn more about how to protect your build.

Have questions? For expert assistance, reach out to your construction design manager or contact 1-800-NATIONAL ® Construction Services.

Why invest in a wall?

Explore more reasons why investing in high-performance gypsum products deliver stronger walls for better outcomes.

Protect your buildingBe the first to hear of new NGConnects Blog posts by subscribing here for early access.