Building Knowledge

Building Knowledge

Safeguarding shafts with impact-resistant drywall

High-rise safety relies on code-compliant shaft enclosures and ASTM standards to protect occupants and first responders

In high-rise construction, shaftwall systems are more than stair and elevator shaft enclosures — they are lifelines. These assemblies safeguard occupants during emergencies while also protecting critical systems and withstanding decades of heavy use. The materials chosen for shaftwall systems can mean the difference between basic code compliance and reliable, long-term safety and resilience.

What is a shaftwall system?

A shaftwall is a non-load-bearing, steel stud partition that provides a 1- to 4-hour fire rating. It’s constructed from one side and is commonly used to enclose elevator, stair or mechanical shafts where fire resistance is required.

Shaftwall systems can also serve as fire-rated interior partitions in areas where construction is limited to one side of the partition or as fire-rated horizontal membranes. Because they are fire rated from both sides, they can be installed in either direction, making them especially useful in situations where one side of the wall is inaccessible, such as adding a fire-rated partition next to an existing wall.

For high-rise buildings in Risk Category III or IV (such as schools and hospitals), as well as any building over 420 feet tall, the International Building Code requires shaft enclosures to meet impact-resistance standards established by ASTM C1629, Standard Classification for Abuse-Resistant Nondecorated Gypsum Panel Products and Fiber-Reinforced Cement Panels.

To ensure code-compliant stairwells, architects turn to Gold Bond® XP® Hi-Impact® Gypsum Board. With its fiberglass mesh-reinforced gypsum core, XP Hi-Impact meets both soft- and hard-body impact requirements of the IBC when installed as the face layer on the tenant side of a 2-hour shaftwall used to enclose a stairwell.

Although stairwells are typically part of the conditioned building, shafts enclosures are not. To help combat moisture in these enclosures, the coated fiberglass mat on Gold Bond® eXP. Shaftliner provides superior water resistance without impeding vapor transmission compared to paper-faced boards. And when impact resistance and mold and mildew resistance are both required for a shaftwall system, Gold Bond® eXP® Interior Extreme® IR Gypsum Panels deliver increased resistance to incidental moisture and wall penetrations.

Products such as these carry forward decades of innovation, but the story of shaftwall systems begins with a landmark project: the World Trade Center. Viewed as an engineering breakthrough upon opening in 1973, the twin towers would, decades later, become a tragic catalyst for strengthening building safety standards.

The development of the shaftwall system

As plans for New York City’s World Trade Center took shape during the 1960s, the building’s record-breaking height demanded a new approach to elevator and stair enclosures. Architects and engineers sought a lighter, more economical alternative to masonry — and identified gypsum board as the solution.

The creation of the gypsum shaftwall system provided an option that was four to five times lighter than traditional methods and offered inherent fire resistance. The system utilized 1” thick x 24” wide gypsum panels friction fit between specially designed studs and tracks to enclose stair, elevator and mechanical shafts. The shaftwall was designed to withstand the positive and negative air pressure forces exerted by high-speed elevators and provide 2-hours of fire resistance.

Following that first application in the World Trade Center, gypsum shaftwall systems became a safety standard for nearly every medium- and high-rise building constructed for the remainder of the 20th century.

Following the September 11 attacks on the World Trade Center, New York City officials enacted Local Law 26, which updated the Building Code and Fire Prevention Code to require impact-resistant stair and elevator enclosures in high-rise buildings. The attacks had revealed that many stair and elevator enclosures were easily compromised by office furniture impaled through the shaftwalls, severely hindering both occupant evacuation and first responder access. These failures underscored the critical need for reinforced, impact-resistant shaft enclosures to enhance life safety in high-rise structures.

As a result, high-rise buildings classified as Risk Category III or IV, as well as any building over 420 feet tall, must meet impact-resistance standards outlined in ASTM C1629.

What’s the difference between soft-body impact and hard-body impact?

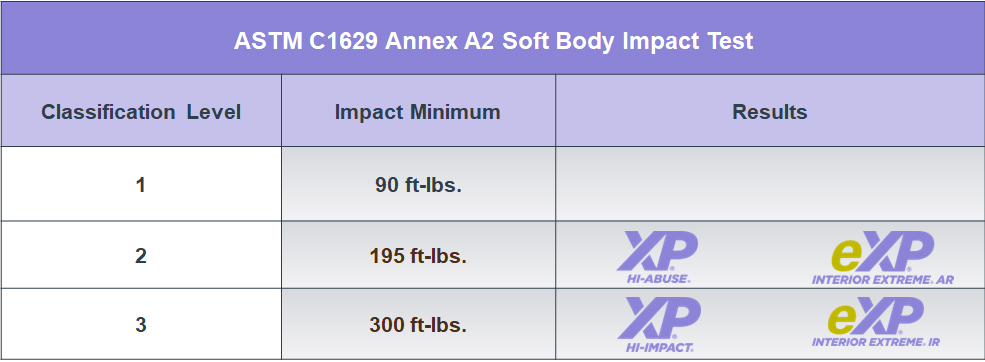

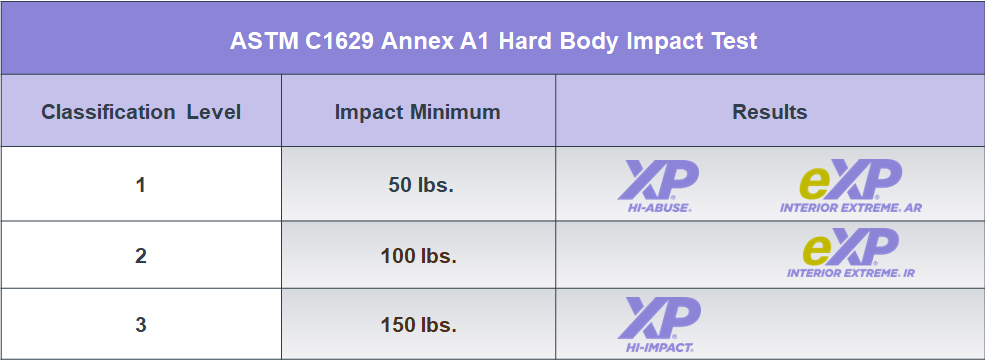

When it comes to impact resistance, not all collisions are created equal. ASTM defines two main types of impact that gypsum wall systems must withstand:

- Soft-body impact (Annex A2 of ASTM C1629): This measures how a wall holds up against larger, cushioned hits — think the force of a shoulder or elbow accidentally striking the surface. While these impacts don’t have sharp edges, they can still cause dents, cracks or surface damage if the wall isn’t properly reinforced.

- Hard-body impact (Annex A1 of ASTM C1629): This test measures resistance to penetration from harder, more intentional strikes, such as a hammer, a boot heel or a fist. Because the force is concentrated in a smaller area, the risk of puncturing the wall and exposing the cavity is much higher.

ASTM C1629 sets the benchmark for how materials are rated against both types of impact. Performance is graded on a Level 1 to Level 3 scale, with Level 3 being the highest rating.

The stair and elevator enclosures in high-rise buildings must meet or exceed a Soft-Body Impact Classification Level 2 and have a layer of impact-resistant material with a Hard-Body Impact Classification Level 3.

For example, Gold Bond®XP®Hi-Impact®Gypsum Board earns a Level 3 rating on both soft- and hard-body impact tests, meaning it provides the maximum level of protection available. That’s important, because in high-rise buildings, particularly stair and elevator enclosures, codes require walls that can resist both soft- and hard-body impacts to help maintain life safety and protect the structure’s integrity.

How to construct a code-compliant shaftwall

High-rise stair and elevator enclosures must do more than resist fire; they also need to withstand incidental impacts, especially during an emergency. To meet code requirements, shaftwall systems are designed and tested for both fire resistance and impact resistance using ASTM standards recognized by the IBC.

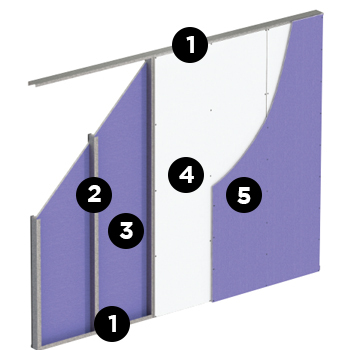

Use W419 for all your shaftwall assembly needs. It provides 1-4 hours of fire resistance from both sides, and when used in conjunction with XP Hi-Impact can meet code required impact standards.

Key components of W419 (2-hour fire rating)

- J-track: Anchors the wall at the floor and ceiling.

- C-T or C-H studs: Minimum 3-1/2"-depth metal studs (20 gauge) spaced 24" on center.

- 1" Gold Bond® Shaftliner XP®: Provides core fire resistance.

- 5/8" Gold Bond® Fire-Shield® Gypsum Board: Base layer that meets or exceeds ASTM C1629 Soft Body Impact Level 2 (195 foot-pounds).

- 5/8" Gold Bond® XP® Hi-Impact® Gypsum Board: Face layer designed to achieve Hard Body Impact Level 3 (150 foot-pounds) protection.

Installation requirements

- Studs and runners: Securely attached to structural members for lateral support, capable of exceeding the Soft Body Impact Level 2 energy requirements.

- Fasteners: No. 8 self-drilling bugle head screws, max 12" on center, meeting ASTM C1002 standards.

- Board staggering: Face and base layer joints must be staggered to strengthen the assembly.

- Controlled inspection: Top and bottom runner installation must be inspected to ensure compliance.

Performance summary

- Fire resistance: Minimum 2-hour rating per ASTM E119.

- Soft-body impact: Meets or exceeds Level 2.

- Hard-body impact: Meets or exceeds Level 3.

- Durability: Multilayered design resists intrusion into the shaft cavity, ensuring safety for occupied areas.

This streamlined system reduces material weight, speeds installation and lowers overall project costs. The result is a code-compliant, impact-resistant shaftwall system that satisfies the most demanding requirements for high-rise life safety.

Resource alert: Use the interactive Fire & Sound Assembly Selector™ to search nearly 350 UL assemblies.

Building for safety and longevity

Stair enclosures and elevator shafts are critical to life safety and building performance. Investing in the right high-performance Gold Bond Gypsum Board for the application isn’t just about code compliance — it’s about providing occupants with a safe passage for evacuation, reducing long-term maintenance costs and providing peace of mind for building owners and designers.

Want to dig deeper into how shaftwall systems work in real-world projects? Explore our blog and get answers to 10 common questions about shaftwall and stair enclosures for commercial buildings. We’ve also got you covered with guidance for designing shaft enclosures in wood-frame buildings.

If you have project-specific questions, contact the National Gypsum experts at 1-800-NATIONAL® Construction Services for tailored guidance and technical support.

Be the first to hear of new NGConnects blog posts by subscribing here for early access.