Timing your finish: working time and open time explained

Understanding how to get peak performance can help turn hard work into a flawless finish

When finishing walls and ceilings, knowing how long your joint compound remains workable can save time, reduce waste and improve the quality of every project. The difference between a perfect finish and extra sanding often comes down to how long your compound stays workable. For joint compounds manufactured by ProForm Finishing Products, LLC, an affiliate of National Gypsum Company, that means understanding two key terms — working time and open time — and how they apply differently to ready mix joint compounds and setting compounds.

Working time for setting compounds

Setting compounds, such as ProForm® Quick Set Lite™, come in powder form and are mixed with water on the worksite to a desired consistency. These products harden chemically, not by air-drying, which means they’re unaffected by humidity once they have hardened and dried.

Working time is the period after mixing when the compound can be applied and tooled before it begins to stiffen. Once that window closes and the product starts to harden, it can no longer be spread easily. ProForm Quick Set Lite provides multiple setting compound formulas in a range of working times — 5, 20, 45, 90 and 210 minutes — to match the project size and finisher’s pace. ProForm Quick Set products offer predictable, consistent set times, so finishers can plan their workflow with confidence.

Pro Tip: Mix only what can be applied within the designated set time. Overmixing or remixing can shorten working time.

Open time for ready-mix compounds

Ready mix joint compounds, such as ProForm® All Purpose, are air-drying materials with longer flexibility in use. Unlike setting compounds, these products don’t chemically harden — they dry through evaporation.

Open time refers to the period during which the ready-mix remains pliable and easy to work after being applied to the surface. A longer open time means more flexibility, which is ideal for large jobs or complex finishing work. Because ready-mix products dry by air, ambient conditions like temperature, humidity and airflow directly affect drying time.

Pro Tip: Keep the environment within recommended conditions (55–95°F) and control airflow to prevent premature surface drying.

Improve your drywall finishing techniques

Ready to elevate your drywall skills? Sharpen your drywall finishing skills with tips and techniques for every step:

- Matching the ideal joint compound with the appropriate finishing tool: Maximize the quality of your finish by pairing ProForm joint compounds with the right tools.

- Joint taping tips and techniques for a seamless drywall finish: Apply drywall paper tape like a pro with best practices that ensure smooth, invisible joints.

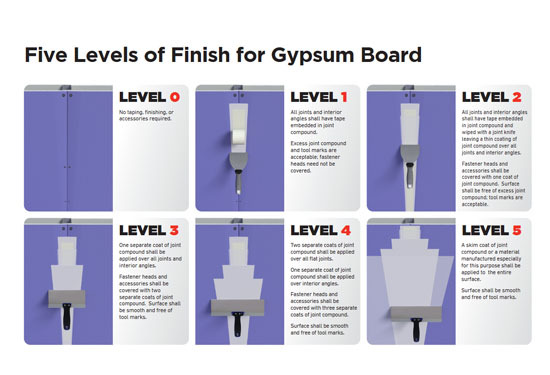

- Level 4 vs. Level 5 drywall finish: key differences explained: Understand the key differences between these two top finishing levels so you can choose the right approach for your project.

- Get a smoother finish with these drywall sanding tips and techniques: Learn how to select the right sanding method, reduce dust, and create a perfectly paint-ready surface.

- How does tinted joint compound improve your finish? Subtly colored joint compounds make imperfections easier to spot, helping you achieve more precise, professional results.

Designed for pros who demand precision, ProForm joint compounds empower finishers to finish fearlessly and achieve results that stand the test of time.

Explore the ProForm Construction Guide to learn more about ProForm’s complete line of both ready mix and setting joint compounds.

View GuideBe the first to hear of new NGConnects Blog posts by subscribing here for early access.