Don't let fire-rated details trip you up!

Most common questions on fire-rated assemblies

Fire-Rated Assemblies: You Have Questions, We Have Answers.

If you have questions about fire-rated wall assemblies, you’re not alone. We’ve gathered the most common questions we hear from professionals like you.

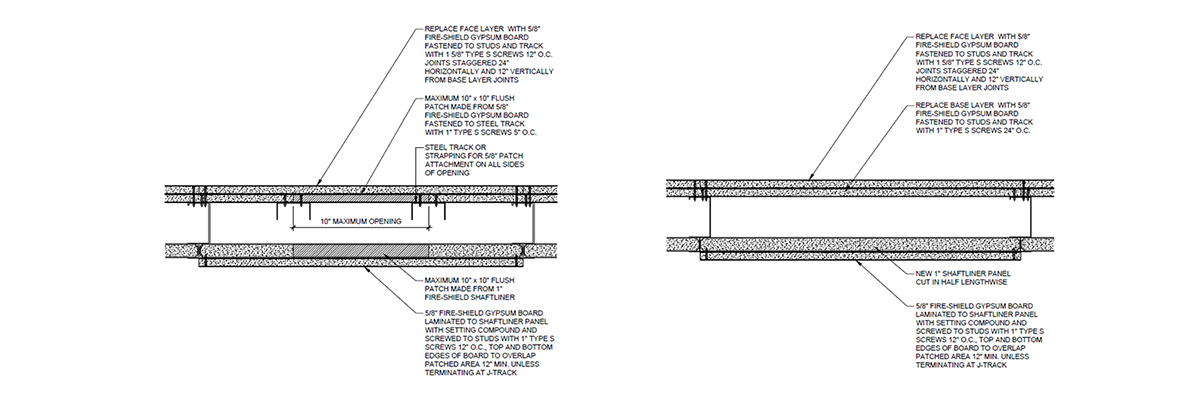

Q: How do I repair holes in cavity shaftwalls?

A: When holes are cut into cavity shaftwall systems (UL design W419), such as pipe or cable penetrations, you must follow specific repair procedures to maintain the fire rating of the shaftwall system.

- For hole penetrations through 1” shaftliner or for crushed or broken core conditions: Square off the damaged area. Cut and fit plugs of 1” shaftliner into the cutout area, ensuring a tight fit. Coat the back of a piece of Gold Bond® Fire-Shield® Gypsum Board (either 1/2” Type C or 5/8” Type X) with setting compound and center it over the patched area, extending 12” above and below the damage on all sides. Secure the Fire-Shield Gypsum Board to the studs on each side with 1” Type S screws 12” o.c. Repair the face panels with a surface-applied patch as described above. When the damage to the shaftliner panel exceeds 100 square inches, the panel needs replacing. For details about replacing the shaftliner panel, refer to The PURPLE Book®, pages 92-93. For more about repairs to the shaftliner panel from outside of the shaft or replacing the shaftliner from the outside of the shaft, consult The PURPLE Book, pages 94-95.

2-hour shaftwall repair details from within the shaft

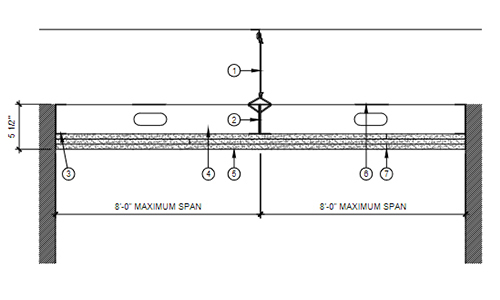

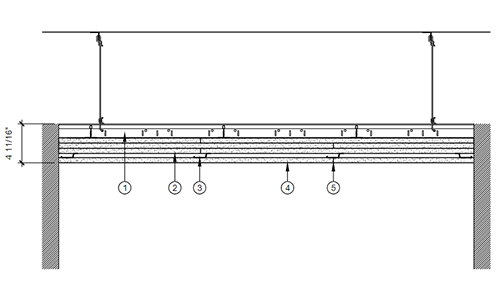

Q: What are some common fire-rated horizontal membranes?

A: Before fire-rated horizontal membranes were developed, architects used UL fire-rated wall assemblies turned horizontally or shaftwall systems for corridor ceilings. To provide another solution, National Gypsum’s 1-800-NATIONAL® Construction Services team developed these horizontal membranes:

- UL design I504: A 1-hour horizontal assembly consists of 3-5/8” steel studs 16” o.c. with three layers of 5/8” Type X Gold Bond® XP® Fire-Shield® Gypsum Board, or other approved gypsum board, on the underside of the framing. This design also spans 8’-0” from wall to wall or indefinitely with the hanger wire spaced nominally 24” oc. It also allows for the use of a premanufactured suspended grid system instead of the steel-stud framing.

- UL design I512: This 2-hour horizontal assembly consists of four layers of 5/8” Type X XP Fire-Shield Gypsum Board, or approved gypsum board, fastened to a premanufactured suspended grid system.

- UL design I516: This 2-hour horizontal shaft wall assembly includes 4” shaftwall studs with 1” shaftliner panels between each stud and three layers of 5/8” Gold Bond® XP® Fire-Shield C™ Gypsum Board, or approved gypsum board, applied to the underside of the framing. It can span 8’ from wall to wall or can be used with the hanger assembly for larger spans.

Q: How do I build a fire-rated wall for an addition, when I can only access one side?

A: One of the most common challenges is how to design a fire-rated assembly in a wall that is accessible from only one side. The National Gypsum 1-800-NATIONAL Construction Services team created two UL fire-rated designs to solve the problem of one-sided fire-rated wall construction. Both have been tested from each side according to the ASTM E119 Standard Test Methods for Fire Test of Building Construction and Materials.

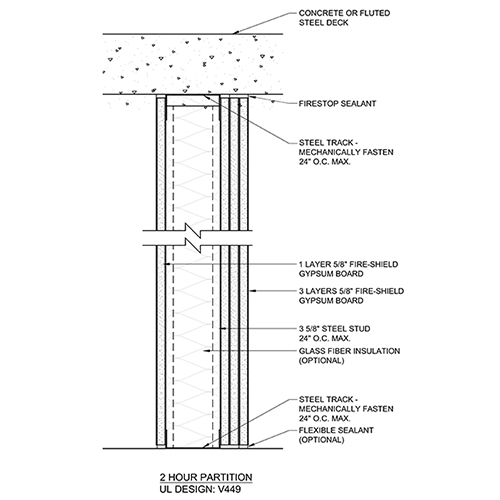

- UL design V449 is ideal for occupancy separations and exterior walls that require a 2-hour fire rating. V449 allows an existing 1-hour fire-rated wall that has one layer of 5/8” Type X gypsum board on each side to be converted to a 2-hour fire-rated wall assembly constructed from one side by adding two more layers of 5/8” Type X gypsum board to just one side. In addition to being a simple solution for occupancy separations, you can also use it for exterior walls that require a 2-hour fire rating.

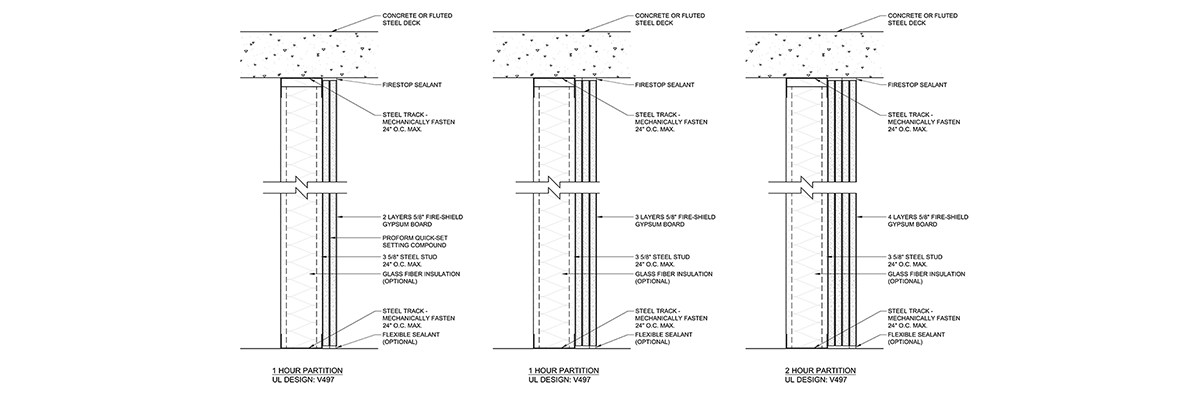

- UL design V497

provides options to construct 1-hour and 2-hour fire-rated wall assemblies from one side.

- 1-hour fire-rated wall: Apply two layers of 5/8” Type X gypsum secured with a layer of setting-type joint compound between them. This design saves space but is more labor intensive. (Refer to page 14 in The PURPLE Book.)

- 1-hour fire-rated wall: Apply three layers of 5/8” Type X gypsum board on one side.

- 2-hour fire-rated wall: Apply four layers of 5/8” Type X gypsum board on one side.

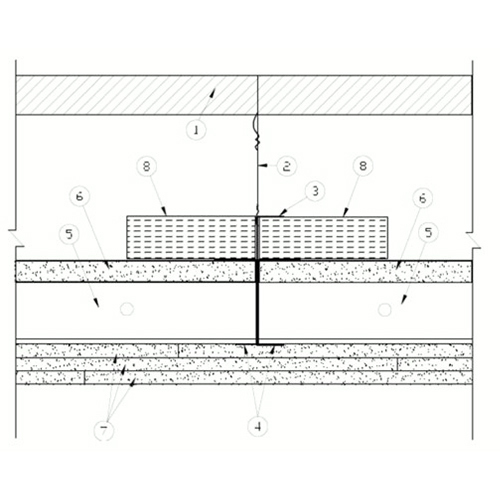

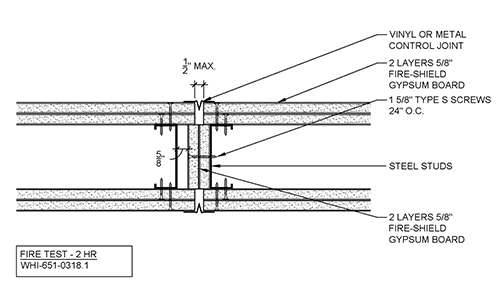

Q: How do I address control joints in fire-rated assemblies?

A:Where control joints occur in acoustical or fire-rated partitions, pay special consideration to the control joint materials to ensure the continuity of the assembly’s fire or STC rating. Refer to the Gypsum Association publications, GA-234-2019 Control Joints for Fire-Resistance Rated Systems and GA-216-2024 Application and Finishing of Gypsum Panel Products to achieve 1- and 2-hour ratings for both wood and steel stud partitions. For additional guidance on designing control joints for fire-rated systems, review The PURPLE Book (pages 38, 58, 66 and 88) and The Wood Book™ (page 27).

“Should you need help with design, or have questions during construction, it’s best to contact the experts. The technical marketing team at National Gypsum is continuing to set the standard for the gypsum industry with answers to your questions. Working outside normal office hours? Our Fire & Sound Assembly Selector tool never sleeps. Our NGConnects Blog and webinar Q&A also produce answers 24 hours a day.”

Thad Goodman

Thad Goodman

Construction Design ManagerNational Gypsum Company"When it comes to fire-rated assembly questions, don’t hesitate to send them our way — we are here to help. Whether it’s a wall access issue, a renovation, a local code question, or simply looking for some best practice UL fire-rated advice, we have you covered. Between our Construction Design team, our 1-800 NATIONAL Construction Services hotline and our powerful resource library, we will get your project over the finish line."

Cathryne Robinson