Innovation

Innovation

Innovating to unlock savings on installation labor and materials

In part three of a three-blog series about National Gypsum’s culture of innovation, explore how the company provides solutions to installation challenges

First introduced in the early 1900s, gypsum board revolutionized the process of creating indoor walls and ceilings. Before the invention of gypsum, these interior partitions were made by layering wet plaster over wooden strips. Creating plaster walls was time-consuming, requiring several coats to be applied and a long drying period before final decoration.

While the promise of a simpler installation process propelled the early adoption of drywall, the innovations by National Gypsum’s three founders helped make it the standard for the construction industry. They formulated their new wallboard to be lighter, stronger and more flexible than any other on the market, which made the product more durable and easier to install.

In the decades since, National Gypsum has continued to introduce innovative products that helped modernize the drywall industry while creating customer touch points that redefined its role as a trusted partner. Along the way, the company also recognized the importance of identifying challenges faced by builders and installers in the field. This, in turn, led National Gypsum’s affiliate manufacturing companies, Gold Bond Building Products, LLC; PermaBASE Building Products, LLC; and ProForm Finishing Products, LLC to develop solutions that improve the installation process of the products it provides.

A faster, more efficient installation can help reduce product waste, limit mistakes and simplify training for new installers. Streamlined training has become particularly important in the current era of labor force shortages.

Let’s explore some recent innovations from National Gypsum and its affiliate companies — Gold Bond Building Products, PermaBASE Building Products and ProForm Finishing Products. Each aimed to solve customer pain points and inefficiencies by developing innovative ways to streamline installation processes and create improvements that save time, money and materials.

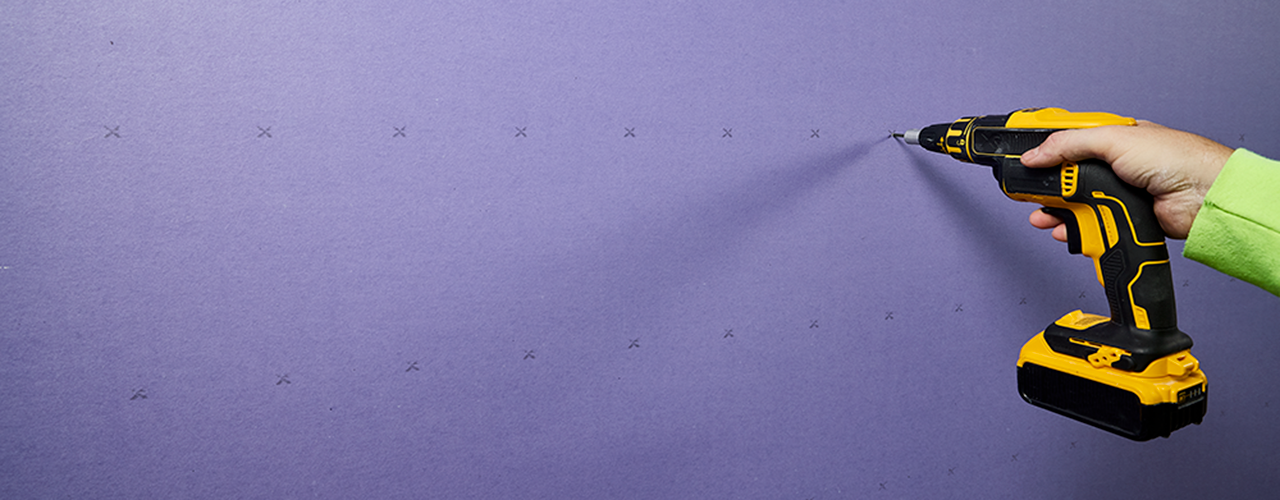

GridMarX: An easy-to-use guide mark system for installing drywall

Standard on gypsum board products manufactured by Gold Bond, GridMarX® installation guide marks are printed on the face paper surface to help installers feel confident in where to put each screw by easily identifying stud locations and spacing. The grid pattern reduces errors or misalignment of fasteners, ensuring accurate and consistent placement of screws or fasteners during installation.

National Gypsum created GridMarX after observing drywall installers at work — where typical installation includes marking lines to identify stud locations, followed by measuring and marking for fastener placement and hanging the board.

GridMarX eliminates this time-consuming process with marks printed on every 4-foot-wide gypsum board product manufactured by Gold Bond. GridMarX guide marks are printed parallel to the long edge of gypsum boards every 4":

- Along both edges

- At 16" from each edge

- Down the center at 24" from each edge

By simplifying the layout and marking process, GridMarX guide marks contribute to increased productivity and dramatically improve the learning curve for new installers or apprentices. They also provide visual cues that help reduce the potential to penetrate hidden utilities, such as pipes and wires, and streamline building inspections.

MaX 12 and MaX 16: Innovative fastener patterns proven to save time and money

Using GridMarX, National Gypsum created the award-winning MaX 12® — the industry’s first 12" on-center optimized fastener pattern for single-layer 1-hour UL fire-rated assemblies on metal framing spaced 24" on-center.

MaX 12 improves upon the industry standard fastener pattern for most UL fire-rated systems and replaces it with a simpler, more efficient method. This results in savings of both installation and finishing labor, as well as material costs for the contractor.

A study by RSMeans data from Gordian, an industry-leading construction cost consultant, determined that using Gold Bond® Fire-Shield® Gypsum Board with GridMarX installation guide marks and the MaX 12 optimized fastener pattern can save applicators up to $70 per thousand square feet.

Following on the success of MaX 12, National Gypsum tested and passed a series of 1-hour fire-rated UL wall designs that require only one fastener every 16" — the MaX 16® optimized fastener pattern on metal framing spaced 16" on center — instead of the industry standard pattern of 8" on the perimeter and 12" in the field of the board.

Using the MaX 16 pattern can save up to 46% in installation time, according to a time/motion study by RSMeans.

The combination of MaX 16 and GridMarX installation guide marks offers many benefits for commercial drywall installers working on buildings with metal framing spaced 16" on center. In addition to the savings on drywall fasteners on a 1-hour fire-rated wall with metal framing, MaX 16 can also reduce training time for new drywall crew members by clearly marking where to install a fastener at every 16" on the gypsum board.

PermaBASE Cement Board: A highly durable alternative to three-coat stucco

Just as gypsum board introduced installation efficiencies that made it an economical choice over the traditional interior lath and plaster, using PermaBASE® Cement Board for exterior stucco walls provides similar labor and installation time efficiencies.

PermaBASE Cement Board reduces both the time-intensive curing process and the number of trips around the structure to complete exterior stucco wall installation, from the required six trips when using a three-coat process to four trips with cement board.

In fact, a time/cost study by Home Innovation Research Labs, an independent subsidiary of the National Association of Home Builders, showed using cement board resulted in a 35% installation time savings over traditional exterior stucco wall installation.

Cement board also reduces the impact of weather conditions on the time required to complete the project, because only the final stucco coating is subject to temperature and humidity tolerances for curing. For traditional three-coat exterior stucco wall installation, the temperature must be between 40 and 90 degrees Fahrenheit to cure each coat. If it’s too cold, the water won’t cure out of the cement. If it’s too hot, it dries too quickly and starts cracking.

Along with being lightweight and easy to work with, PermaBASE Cement Board also has high-performance features, including:

- Moisture and mold resistance

- UL GREENGUARD Gold certification

- EdgeTech® Reinforced Edge technology for added durability

PermaBASE WP: A waterproof substrate for modern shower enclosures

As large walk-in showers — with features such as floor-to-ceiling tiled walls and built-in niches and benches — grow in popularity, ensuring a waterproof enclosure has become critical for builders. These features require more grout, which increases the likelihood of water damage and can result in mold, mildew and wood rot.

To provide the industry with a reliable solution, PermaBASE took the strength and benefits of its PermaBASE Cement Board and integrated a proprietary waterproofing formulation to create PermaBASE WP® Waterproof Cement Board. Intended for use in interior wet areas around tubs and showers, PermaBASE WP is perfect for instances where liquid waterproofing has historically been applied over cement boards.

Using PermaBASE WP can result in significant cost savings because installers typically use 75% less liquid waterproofing/sealant for a shower enclosure installation. PermaBASE WP also features EdgeTech reinforced edges. This allows for closer fastener application of nails or screws at the edge without crumbling or spinout, and a smooth board surface for installing tile and other decorative finishes.

Dust-Tech: A technology that reduces airborne dust when sanding joint compound

The sanding of the dried joint compound to achieve a uniform, flat appearance is a key step in completing any drywall installation. Due to the nature of joint compound, when sanded, it breaks down into fine particles that are lightweight and can easily become airborne.

Plastic sheeting and painter’s tape can only contain so much of the dust during a project. This, in turn, becomes especially challenging for renovation and retrofit projects where the building or home remains occupied.

To help minimize the airborne dust created during the sanding process, ProForm developed an innovative solution called Dust-Tech® technology. Dust-Tech significantly reduces airborne dust during drywall sanding by producing larger particles that drop to the floor versus floating in the air.

Available for both ProForm® All-Purpose Joint Compound and ProForm® Lite Blue® Joint Compound, Dust-Tech can reduce airborne dust while sanding by up to 60%. This reduces its impact on indoor air quality during all phases of drywall finishing, texturing, patching and renovations.

In addition to cleaner air, the time saved on cleanup is a significant benefit of ProForm Dust-Tech for drywall installation crews, since less airborne dust results in fewer surfaces to clean.

Innovation across the board

As National Gypsum marks its 100th anniversary in 2025, the company continues to deliver innovative solutions that help improve the high-performance gypsum products industry. From new products and world-class customer service to unmatched technical support and time-saving installation processes, National Gypsum remains committed to helping its customers design and build better.

Explore National Gypsum’s full line of innovative brands to find the right solution for your next project.

Be the first to hear of new NGConnects blog posts by subscribing here for early access.