Building Knowledge

Building Knowledge

Control Joints: What you need to know

Specifying and installing drywall control joints to prevent cracking

When designing interior spaces that incorporate long expanses of gypsum board walls and ceilings, an often-overlooked component of the wall assembly is the control joint. These predetermined separations in the gypsum board membranes are designed to relieve internal stresses created by expansion and contraction of the framing members or slight movements in the wall caused by structural loads, changes in air pressure, doors closing or vibrations from foot traffic.

What is a drywall control joint?

Technically, control joints are gaps in the gypsum board, but they also refer to plastic or metal decorative trim pieces installed in the gaps to provide a decorative finish. Other methods of treating control joints include filling the joints between gypsum board panels with acoustical or fire-rated sealants.

Source: GA-216

Source: GA-216Control joints, like the example above, accommodate a building’s movement by providing a controlled area for the framing to expand and contract, reducing the strain on the gypsum board.

What are the requirements for control joints?

Gypsum board is required by the International Building Code (IBC) to be installed in accordance with The Gypsum Association technical document GA-216-2021: Application and Finishing of Gypsum Panel Products or ASTM C840, Standard Specification for Application and Finishing of Gypsum Board.

Both documents include the following requirements for the installation of control joints:

- Control joints shall be either manufactured devices designed for this purpose or field fabricated from suitable materials.

- Control joints shall be installed where indicated on the plans. Full height door frames shall be considered equivalent to a control joint.

- A control joint shall be installed where a partition, wall or ceiling traverses a construction joint (expansion, seismic or building control element) in the base building structure.

- Control joints shall be installed where a wall or partition runs in an uninterrupted straight plane exceeding 30 linear feet (9 m).

- Control joints in direct applied interior ceilings, and suspended ceilings without perimeter relief, shall be installed so that linear dimensions between control joints do not exceed 30 ft. (9 m).

- Control joints in suspended ceilings with perimeter relief shall be installed so that linear dimensions between control joints do not exceed 50 ft. (15 m).

- Control joints in exterior ceilings and soffits shall be installed so that linear dimensions between control joints do not exceed 30 ft. (9 m).

- A control joint or intermediate blocking shall be installed where ceiling framing members change direction.

- Control joints shall be installed where specified by the architect or designer as a design accent or architectural feature.

The details below from the GA-216 outline the proper joint location of gypsum board joints to prevent cracking and the need for control joints.

Source: GA-216

Source: GA-216“Cracking at the corners of openings for doors and windows is a common problem. To prevent this, the GA-216 prohibits gypsum board joints within 12 inches (300 mm) of the corners of openings unless control joints are installed at those locations. So to prevent the need for unsightly control joints at the corners, ensure that the gypsum board is installed accordingly.”

Sam Halverson

Sam Halverson

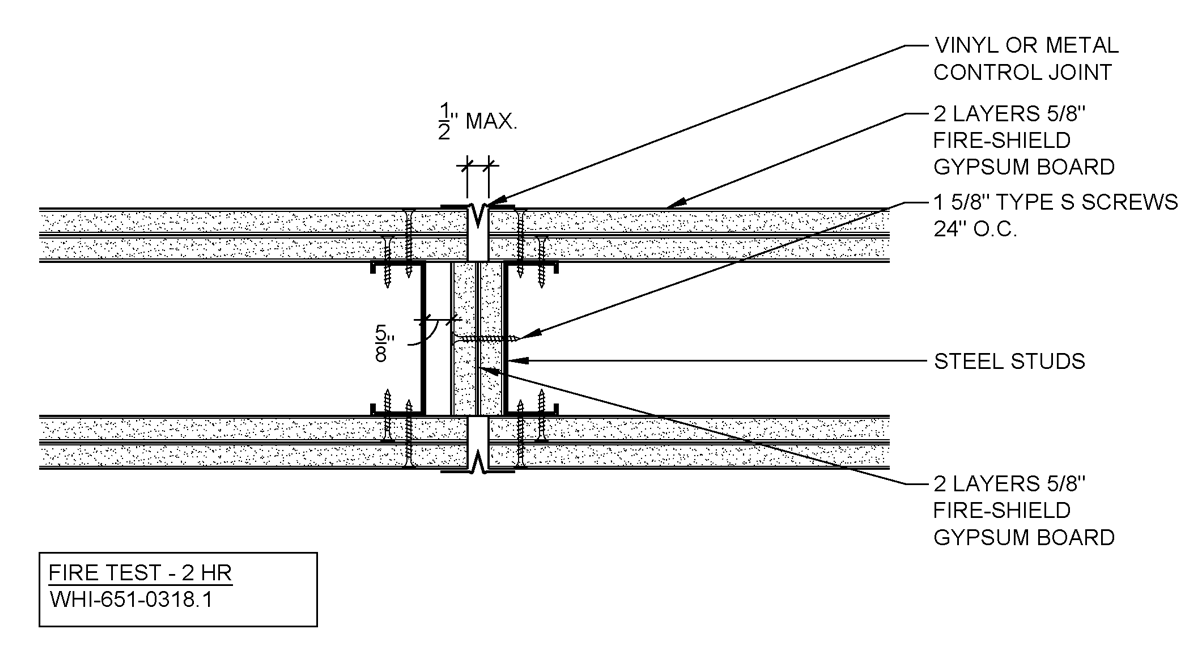

Construction Services ManagerNational Gypsum CompanyControl joints in fire-rated systems

Where control joints occur in acoustical or fire-rated partitions, special consideration should be paid to the control joint materials to ensure the continuity of the fire or STC rating. See the Gypsum Association publication, GA-234-2019 Control Joints for Fire-Resistance Rated Systems to achieve 1- and 2-hour fire ratings for both wood and steel stud partitions.

Resource Alert: Review National Gypsum’s The PURPLE Book® (pages 38, 58, 66 and 88) and The Wood Book™ (page 27) for additional guidance on designing control joints for fire-rated systems.

Source: The PURPLE Book, page 38

Source: The PURPLE Book, page 38How to specify control joints

Architects should, and typically do, specify that gypsum board should be installed per the GA-216 or ASTM C840. This ensures that control joints are included in their contract documents but does not dictate their location. Where aesthetics are a concern, control joint locations should always be included in the drawings to prevent their installation in an undesirable location.

5 tips for installing control joints

1) Where aesthetics are the primary concern, can I reduce or eliminate the use of control joints?

No, not without running the risk of cracking.

2) Does the gypsum board thickness affect the design of the joints?

No. The design of the control joint is the same for all gypsum board, regardless of thickness (1/2" or 5/8").

3) Should I install control joints on exterior gypsum sheathing?

The standard for the installation of gypsum sheathing, ASTM C1280, Standard Specification for Application of Exterior Gypsum Panel Products for Use as Sheathing, does not require control joints for the sheathing. Refer to the cladding manufacturer for any control joint requirements that they may have.

4) Does the framing material matter when designing control joints? Is the design different for wood-framed assemblies versus steel-framed assemblies?

No. The gypsum board control joint guidelines are the same for both.

5) Is there a preference for the control joint material?

No, both vinyl and metal control joints are acceptable.

Need more information or assistance with designing and installing control joints? Contact the technical experts on National Gypsum’s Construction Services team at 1-800-NATIONAL®.

Be the first to hear of new NGConnects blog posts by subscribing here for early access.